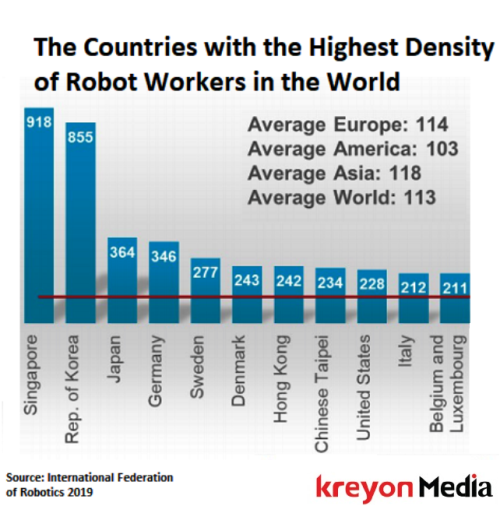

The rise of machines and automation has been accelerating with rapid pace. The world is increasingly driven by machines, robots, technology and data driven algorithms. A study by the International Federation of Robotics reveals that the number of industrial robots has gone up. In 2020, the number of industrial robots per 10,000 workers is 113, back in 2016 there were 74 robots per 10,000 workers. The study also shows the highest density of robot workers around the world.

The developed world is using automation and robotics for manufacturing like never before. Companies like Tesla are using a very high degree of automation and robotics for car manufacturing in its Nevada center. The electrical car maker has done nearly

cent percent manufacturing using robots with minimal human beings for overseeing workers.

Amazon uses robotics for its warehouses. It uses fulfillment robots for stacking & despatching items in its warehouse. The ecommerce giant also uses drone based delivery options for its customers. Shimizu Corporation from Japan has invested heavily in construction robots. The company now uses construction robots to meet the manual labour needs for work. There are self-service checkouts in supermarkets for billing and purchases.

The robots & automation is being used for screening documents and identity checks. There is a case for the growing proliferation of robots for replacing human jobs. Human drivers will be replaced by robots. Companies like Google, Uber & Tesla are in advanced stages with self driving cars. A McKinsey report from 2017 predicts that robots will take over 800 million jobs by 2030. This will mean nearly 20 percent of the global workforce will be affected due to robots and automation.

The concern of coronavirus & spreading infection is increasing the use of robots and automation. Companies are opting for building contactless models where they can operate with minimum labour involvement, continue to operate with efficiency and yet save their costs in the long run. Use of robots and automation doesn’t always lead to job loss, infact, many times companies still need people to install, operate and maintain robots. So, the people need to be re-skilled to work alongside robots and automation.

Asia has a robot density of 118 units per 10,000 workers, Europe has 114 units & America has 103. The world average of robots per 10,000 workers stands at 113. Robots have been used in various industrial applications for manufacturing across industries. The automotive, electrical & electronics, metal & machinery are the top three industries where industrial robots are used.

Singapore has the highest density of industrial robots in the world currently. There were 918 industrial robots used per 10,000 employees. Singapore has been pushing to modernise its infrastructure, leveraging digitization and robotics for its manufacturing industries.

South Korea has the highest density with 855 industrial robots per 10,000 workers. The high number of robots is mainly used for manufacturing in the electrical & electronics industry. South Korea had 710 robots per 10,000 workers in 2017. Japan is second on the list with 364 industrial robots, closely followed by Germany with 346 robots per 10,000 workers. Germany and Japan are renowned for their automotive industries and they have density levels of just around 350 per 10,000 workers. Interestingly, Japan is one of the main players in industrial robotics, accounting for over half of the global supply.

Sweden has 277 units per 10,000 workers installed, followed by Denmark with 243 & Hongkong with 242. Taiwan is seventh on the list, followed by the US on the eighth position. They have 228 & 212 units respectively. The European countries Italy, Belgium & Luxembourg complete the ninth and tenth slots.

China is expanding aggressively, it has 187 units per 10,000 workers as of 2019. But it is a major end user for the robots industry. In the next few years, China is well poised to be among the top 10 players employing robots. The top technology companies in China like Tencent, AliBaba & AntFinancial are some of the big names that are investing heavily into robotics & automation.

Digitization is on the rise with Covid-19. The software & electronic industries seem to be gaining an advantage with the social distancing and prolific use of technology. Companies and governments are ramping up their efforts to modernise and digitise their manufacturing and production. Many companies are finding innovative ways for SaaS applications development for their customers. For e.g. wealth management companies are creating subscription based platforms to engage with their customers for recommending them personalised investment & insurance options.

The increasing demands of applications for performing consumer centric services, use of industrial robots for manufacturing and disrupted supply chains are the after effects of pandemic. The cloud and 5G technologies are pushing these developments. As the world adapts to the new normal, the future will be driven by growing coexistence of humans and robots.